Some Ideas on Inventory Management You Should Know

Wiki Article

Inventory Management Fundamentals Explained

Table of ContentsFascination About Inventory ManagementGetting My Inventory Management To WorkThe Best Guide To Inventory ManagementThe Only Guide to Inventory Management

JIT stock management can be high-risk. If demand suddenly increases, the producer may not have the ability to source the inventory it needs to satisfy that need, damaging its reputation with customers and driving company towards rivals. Also the smallest hold-ups can be bothersome; if an essential input does not arrive "just in time," a bottleneck can result.

The EOQ design seeks to ensure that the correct amount of inventory is bought per set so a business does not have to make orders too regularly and there is not an excess of inventory remaining on hand - Inventory Management. It thinks that there is a trade-off in between supply holding prices and supply setup costs, and total supply prices are reduced when both configuration prices as well as holding costs are lessened.

DSI is additionally called the typical age of inventory, days stock exceptional (DIO), days in stock (DII), days sales in inventory or days inventory and is translated in multiple ways. Suggesting the liquidity of the stock, the figure represents the number of days a company's current stock of inventory will last.

Some Ideas on Inventory Management You Need To Know

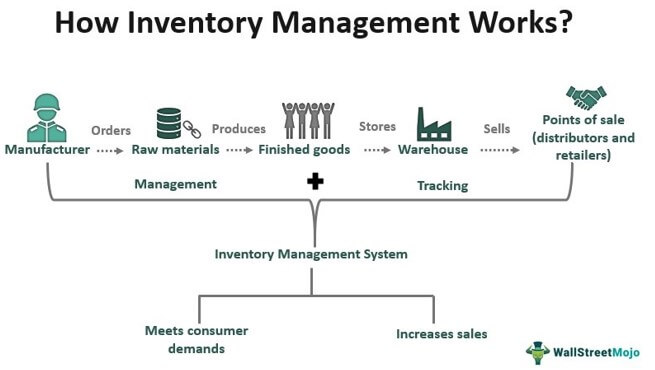

If a firm frequently switches its method of stock bookkeeping without reasonable reason, it is most likely its monitoring is trying to paint a brighter image of its company than what holds true. The SEC needs public companies to disclose LIFO get that can make supplies under LIFO costing comparable to FIFO setting you back.This can also elevate warnings with a business's ability to remain competitive and also manufacture items that interest customers moving forward. The 4 kinds of inventory management are just-in-time administration (JIT), products need preparation (MRP), economic order amount (EOQ), and also days sales of stock (DSI). Each supply management design works much better for different services, and also there are advantages and disadvantages per type.

"Supply is like dairy products," Chef is quoted claiming. "Nobody wishes to buy ruined milk." Therefore, supply management can conserve a firm millions. Allow's consider an instance of a just-in-time (JIT) stock system. With this approach, a company obtains items as close as possible to when they are actually needed.

Stock management is an important component of organization operations. Proper stock monitoring depends on the kind of organization and what kind of item it offers. There may not be one excellent type of supply monitoring, because there are pros and cons to every. Yet benefiting from one of the most suitable kind of inventory management design can go a long way.

Not known Details About Inventory Management

When it comes to supply administration, there's good news and there's bad news for lots of services. Inventory administration can be a complicated task, which is why firms often stay clear of re-evaluating their procedures.While it might be tempting to adhere to a status-quo strategy, your inventory monitoring system can in fact make or break your organization carrying out a reliable as well as effective system can be a surprise secret to success. Inventory Management. What is Stock Management? Read on to learn why supply administration systems matter and also exactly how you can utilize the appropriate system to assist your organization be more efficient as well as lucrative.

Supply monitoring, however, is greater than just a simple tally of stock. A well-managed stock system lets your organization make the many of its storage space areas, much better offer clients by having the stock that they desire (when they desire it), as well as conserve cash by decreasing costs and also losses because of perishing as well as theft.

Efficient supply management can be a beneficial tool, giving insight right into essential aspects of your organization, including: Your economic standing, Customer actions, Product as well as service opportunities, Future trends To reveal the power of stock administration systems on company success, let's look to the striking example of Kmart and also Walmart during their rate war in the 1990s - Inventory Management.

The Best Strategy To Use For Inventory Management

Their aptly named "just-in-time inventory" system reduced excess find here supply, which liberated cash money that could after that be invested into service growth. In addition, this more-efficient system given far better insight into consumer requirements which made it feasible for the business to use even more of the products that consumers wanted at a lower price and also a reduced rate for consumers.Throughout the exact same time duration, Kmart stuck find more with their typical inventory administration process. The outcomes promote themselves: Between 1998 and also 2000, Kmart supply prices dropped 63%, while Walmart stocks climbed by 82%. In the very early 2000s, Kmart's decline proceeded. The firm declared insolvency in 2002, closed thousands of Kmart shops, as well as ultimately combined with Sears Roebuck in 2005.

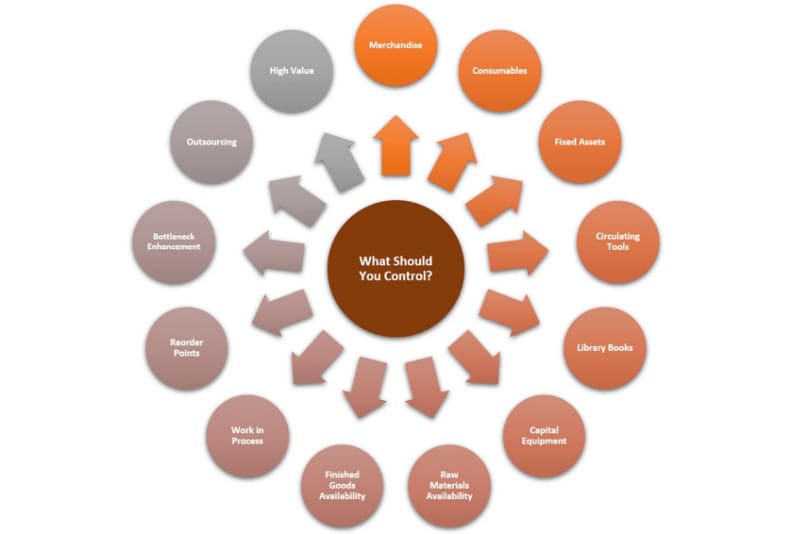

While the particular type of stock that your transaction with may vary significantly depending upon whether your organization is concentrated on wholesale, retail, or manufacturing, the essential principles of exactly how you handle inventory are global. If we think about stock as cash, taking control of your inventory and also maximizing what you have (while reducing stock also known as cash waste) is vital.

In order to create better exposure of stock degrees, a reliable stock administration system need to leverage aspects like: You'll also intend to evaluate the sort of inventory administration helpful hints system you utilize as this can influence exactly how well you see your inventory. In order to better recognize just how well your stock system is offering your service, let's consider two vital techniques to handling your stock: periodic and also continuous inventory systems.

Report this wiki page